From Crude Oil to Gasoline: Unveiling the Complex Journey of Fuel Refinement

Article

Oct 16, 2024

Have you ever wondered where your car’s fuel originates from? The journey from crude oil to gasoline is a modern transport and industry marvel. Understanding this complex process is important for each of us, as it provides a different perspective on the resource we encounter every day, yet still take for granted.

Once crude oil is extracted from beneath the earth's surface and transported to refineries, the refining process can begin. Experts test each batch to determine its characteristics, the composition varies based on geographical origin, meaning not all crude oil is the same. A tailored approach to each batch during refining enables the production of high-quality fuels.

The Basis of Refining

The first phase of the refining process is distillation. In a distillation tower, crude oil is heated until it reaches its boiling point and begins to vaporize. As the vapor rises through the tower, it is being separated into various fractions based on their boiling points. This is enabled by a special design of the distillation tower which has multiple trays or columns, allowing for separation.

Lighter byproducts, such as gasoline and propane, ascend to the top of the tower, where cooler temperatures allow them to condense back into liquid form. Meanwhile, heavier byproducts, like diesel, kerosene, and lubricating oil,s settle at lower levels, where the temperatures are higher, preventing them from vaporizing. A careful separation process ensures that each fraction can be collected and further refined for various specific purposes and uses.

Unlocking the Potential of Hydrocarbons

During the conversion phase, a method called cracking takes place. This method involves heating up large hydrocarbon molecules, or compounds made up of hydrogen and carbon atoms, which breaks them down into smaller, more useful molecules. This transformation is vital to produce gasoline that meets the high-performance demands of modern vehicles, which require fuel that can withstand high compression and temperatures.

Another important method, reforming, helps rearrange the molecular structure of hydrocarbons to enhance their properties. This rearrangement helps increase the octane ratings of the fuel, as high-octane fuel is essential for optimal engine performance, being able to resist knocking (premature combustion) under high pressure and temperature conditions within an engine.

It is during these conversion stages that crude oil is transformed into the gasoline that powers the cars, trucks, and countless other machines within our society, enabling them to operate efficiently and effectively.

Important Role of Additives

The next phase involves blending additives into the fuel to improve its quality. For example, detergents help clean the engine and prevent deposit buildup, which keeps it running smoothly over time. Antioxidants are added to prevent the fuel from oxidation, or "going bad", when it's stored for longer periods, extending its stability and shelf life. Other additives, such as corrosion inhibitors, protect metal parts of the engine from rust and corrosion, while octane boosters ensure smoother combustion and prevent engine knocking.

As regulations push for cleaner fuels, additives like oxygenates help reduce harmful emissions, making the fuel burn more completely and be more efficient, improving the engine performance at the same time.

Ensuring Fuel Quality

After the refining process is complete, refined fuel is transported via pipelines, ships, or trucks to distribution terminals, where it undergoes one final round of testing to ensure it meets regulatory standards and specifications before it is sent out to local gas stations. This additional testing typically includes:

Quality testing: The chemical composition of fuel samples is analyzed to confirm that they align with the required quality standards.

Contaminant detection: As contaminated fuel could damage the engine or reduce its performance, testing for water, sediment, or other impurities is conducted to ensure the fuel is clean and safe for use.

Performance assessment: Sometimes tests include performance evaluation, which helps show how the fuel performs in various conditions. It can include checking fuel stability and emissions potential, which ensures that fuel will function effectively and environmentally responsibly.

Economic and Environmental Innovations

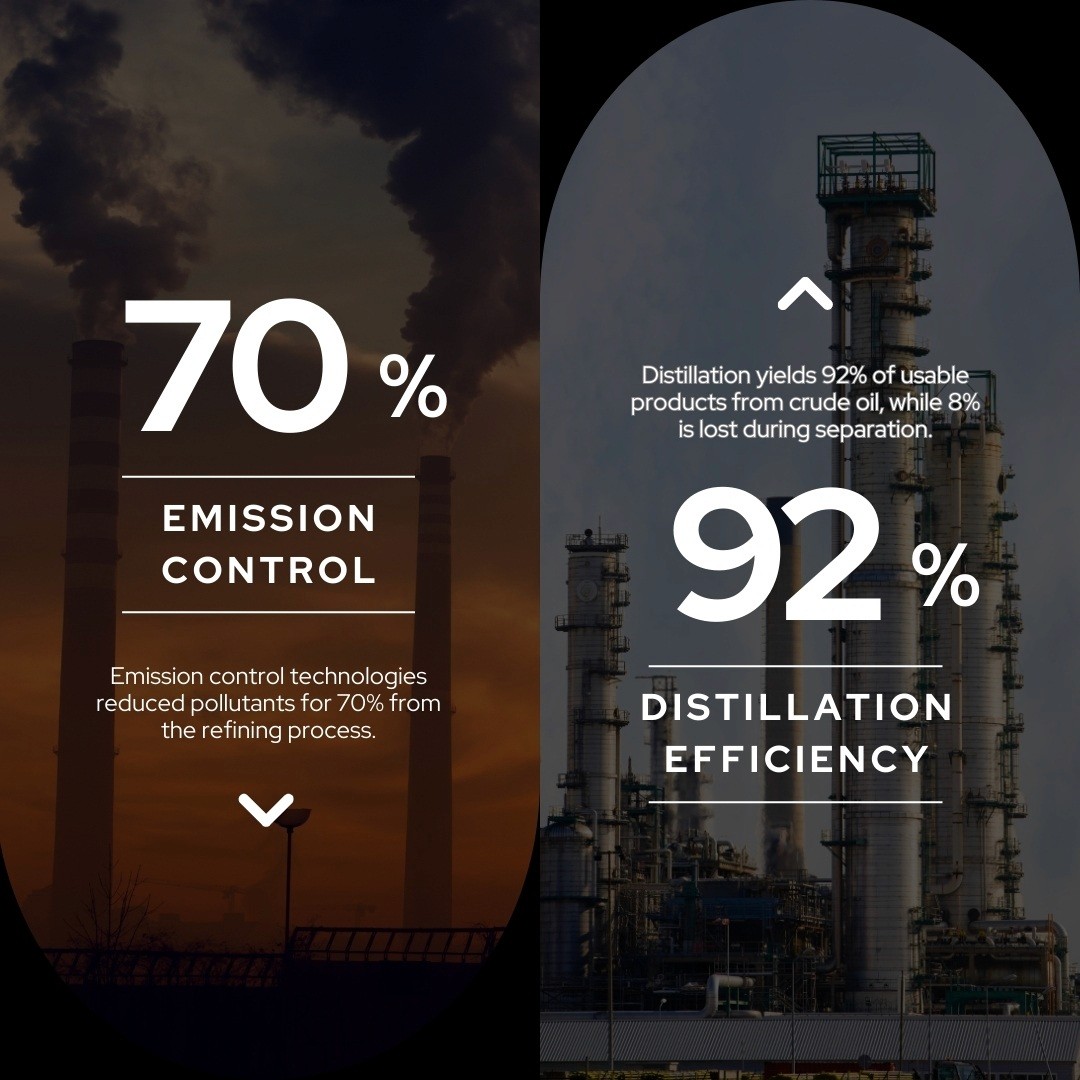

Growing emphasis on sustainability and reducing the carbon footprint associated with fossil fuels has led to the emergence of innovative technologies that improve refining processes, making them cleaner and more efficient. Carbon capture and storage (CCS) technologies, for example, aim to capture greenhouse gas emissions from refineries and store them underground, which prevents them from entering and harming the atmosphere.

In addition, distillation yields are growing thanks to improvements in the process. These improvements include things like advanced heat integration techniques, which recover and reuse excess heat within the refinery and minimize energy consumption, or digital monitoring and control systems that enable fine-tuning refinery operations in real-time, reducing waste while increasing the overall productivity.

The journey from crude oil to gasoline is a complex, multifaceted process that is constantly advancing to enhance efficiency and production capacity while adhering to sustainability standards.

On this page